Glossary Of Terms

Not sure what something on our site means? This glossary of helpful terms will try to clear things up! Call Certified Chimneys

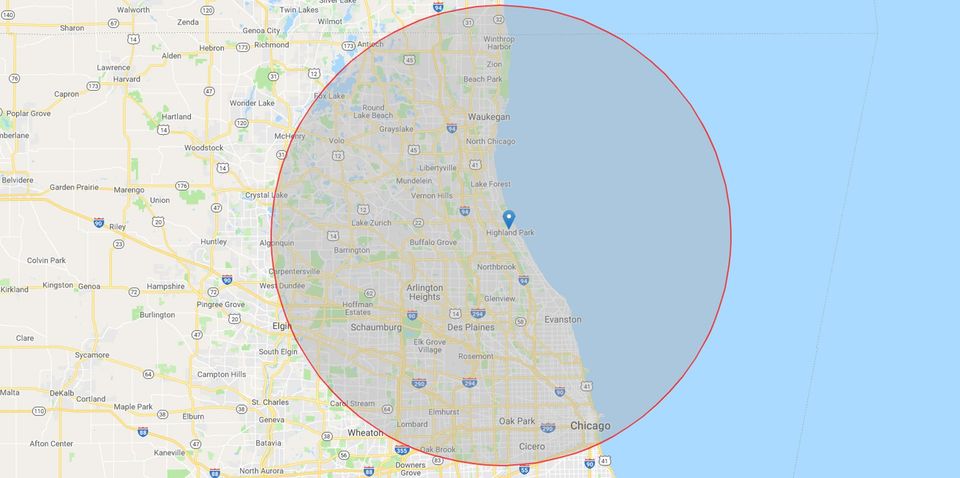

in Highland Park, IL

with any questions about our services or to find out what we can do for you!

ACCESSIBLE (for Inspections)

Capable of being exposed for inspection, maintenance, or repair without damage to the chimney or building structure or finish, but which may require the removal of doors, panels, or coverings using commonly available tools.

BOND

Where referring to bricklaying and masonry chimneys, that connection between brick, stone, or other masonry units formed by lapping them upon one another in carrying up the work, thereby forming an inseparable mass.

BREECHING

The conduit conveying flue gas from the appliance to the chimney.

BTU

Abbreviation for British thermal unit. The quantity of heat needed to raise the temperature of 1 pound of water 1F.

BUILDING CODE

A set of rules and regulations established by local government, which determines the standards for procedures and materials in construction.

CHIMNEY

flues, or channels, through which smoke is expelled from a fireplace or furnace; A structure containing one or more vertical or nearly vertical passageways for conveying flue gases to the outside atmosphere.

CHIMNEY CAP

A protective covering or housing for the top of a chimney intended to prevent the entry of rain, snow, animals, and birds, to prevent downdrafts

CHIMNEY CONNECTOR

The pipe that connects a fuel-burning appliance to a chimney.

CHIMNEY EXHAUST FAN

Mounted on top of the chimney to help create proper draft and aid in combustion. Properly sized and installed these fans present positive solutions to fireplace smoking and severe down drafting.

CHIMNEY FLUE

The passage in a chimney for conveying the flue gases to the outside atmosphere.

CLEARANCE TO COMBUSTIBLES

The distance between a heat-producing appliance, chimney, chimney connector, vent, vent connector, or plenum and other combustible surfaces.

CO

Carbon monoxide.

CO2

Carbon dioxide.

CONCRETE CHIMNEY CAP

(frequently called Chimney Crown) is the top element of a masonry chimney. It covers and seals the top of the chimney from the flue liner to the chimney edge.

COMBUSTIBLE MATERIAL

Material made of or surfaced with wood, compressed paper, plant fibers, plastics, or other material that can ignite and burn, whether flame proofed or not, or whether plastered or un-plastered.

CONDENSATION

Droplets of water sometimes appearing as frost on inside surfaces of exterior walls or windows in cold weather, and caused by excessive moisture-laden air in poorly ventilated buildings.

CORBEL

Units of masonry projecting from or projecting upward and outward from the face of a wall or chimney in courses to form a support or ledge for a beam, rafter, or other member.

DAMPER

A metal device to regulate draft in the flue of a boiler, furnace or fireplace; A valve or plate for controlling draft or the flow of gases, including air.

DEW POINT

The temperature at which water vapor in the air begins to condense into droplets.

DILUTION AIR

The air that enters the relief opening of a draft hood or draft diverter, or the air that enters another opening in an appliance flue or venting system.

DIRECT VENT APPLIANCE (Sealed Combustion System Appliance)

A system consisting of an appliance, combustion air and flue gas connections between the appliance and the outside atmosphere, and a vent cap supplied by the manufacturer, and constructed so that all air for combustion is obtained from the outside atmosphere and all flue gases are discharged to the outside atmosphere.

DRAFT

The difference between atmospheric pressure and some lower pressure existing in the furnace stack or gas passages of a steam generating unit; The pressure differential that causes the flow of air or gases through a chimney, gas vent, or venting system.

DRAFT HOOD

A device built into an appliance, or made a part of the vent connector from an appliance, that is designed to (1) provide for the ready escape of the flue gases from the appliance in the event of no draft, back draft, or stoppage beyond the draft hood, (2) prevent a back draft from entering the appliance, and (3) neutralize the effect of stack action of the chimney or gas vent upon the operation of the appliance.

EFFICIENCY

The ratio of output to input.

EFFLORESCENCE

A growth of salt crystals on a surface caused by evaporation of salt-laden water.

FACE BRICK

A type of brick made of selected clays and often textured which is highly water-resistant.

FACTORY-BUILT FIREPLACE

A fireplace composed of listed, factory-built components assembled in accordance with the terms of its listing.

FLUE GASES

Combustion products from fuel-burning appliances along with excess air.

FIREBRICK

A brick made of special fire clay to resist high heat.

FIRE CLAY

Material that can withstand very high temperatures without softening or fusing and to line chimney flues and fire chambers of boilers and furnaces.

FIREPLACE

A hearth, fire chamber, or similarly prepared area and a chimney.

FIREPLACE ACCESSORIES

Accessories intended for field installation into or attachment to existing masonry fireplaces. These include such items as heat exchangers, door assemblies, tubular grates, and blowers.

FLASHING

Sheet metal or other material used around chimneys, dormers, windows and joints where angles meet to protect a structure from water seepage.

FLUE

An enclosed chimney passage through which gas and smoke rise to open air; The general term for a passage in a chimney for conveying the flue gases to the outside atmosphere; A passage for products of combustion.

FLUE LINING

Round or square fire clay or terra-cotta pipe made in two foot lengths which prevents smoke and hot gases from escaping through the wall of the chimney into the house.

GAS VENT

A passageway composed of listed factory-built components assembled in accordance with the terms of listing for conveying vent gases from gas appliances or their vent connectors to the outside atmosphere.

HEADER

Where referring to chimneys, a beam set at right angles to floor or roof joists to provide support and framing around the opening.

HEARTH

The floor of a fireplace, including the part that extends into the room constructed of tile, brick or stone; The floor area within the fire chamber of a fireplace or a fireplace stove.

HEAT EXCHANGER

A chamber in which heat resulting directly from the combustion of fuel, or heat from a medium such as air, water, or steam, is transferred through the walls of the chamber to air passing through the exchanger; or a chamber in which heat from electric resistors is transferred to the air.

HEARTH EXTENSION

The noncombustible surfacing applied to the floor area extending in front of and at the sides of the hearth opening of a fireplace or a fireplace stove; also where applied to the floor area beneath a fireplace stove or beneath an elevated overhanging fireplace hearth.

JAMB

The upright piece forming the side of an opening as of a door, window or fireplace.

KNEE WALL

Where referring to masonry chimneys, a course, a thickness, or a continuous vertical section of masonry separating flues in a chimney.

MASONRY

Anything built of materials such as concrete, stone, brick or tile.

MASONRY CHIMNEY

A field-constructed chimney of solid masonry units, bricks, stones, listed masonry chimney units, or reinforced Portland cement concrete that is lined with suitable chimney flue liners and built in accordance with the provisions of Chapter 4 of this standard.

MASONRY FIREPLACE

A hearth and fire chamber of solid masonry units, such as bricks, stones, listed masonry units, or reinforced concrete, provided with a suitable chimney.

MASONRY FIREPLACE LINTEL

The horizontal, noncombustible member, usually of masonry or steel, spanning the opening of a masonry fireplace to support the load above.

MECHANICAL DRAFT

Draft produced by a fan or an air or steam jet. When a fan is located so as to push the flue gases through the chimney or vent, the draft is forced. When the fan is located so as to pull the flue gases through the chimney or vent, the draft is induced.

MORTAR

A mixture of cement, sand and water used to bond bricks and stone.

NATURAL DRAFT

Draft produced by the difference in the weight of a column of flue gases within a chimney or vent and a corresponding column of air of equal dimension outside the chimney or vent.

NFPA

National Fire Protection Association, or "NFPA," publishes codes and standards related to fire safety. NFPA 211, entitled Standard for Chimneys, Fireplaces, Vents, and Solid Fuel-Burning Appliances, contains valuable guidelines for the safe installation, use and maintenance of chimneys.

NFPA 211 THREE LEVELS OF INSPECTIONS:

Level 1 specifies the minimum actions required for a routine annual inspection, which includes making sure that the chimney or vent is free of combustible deposits and obstructions, checking for basic soundness regarding the installation of the fuel-burning appliance and its connections, and making visual inspection of all parts of the exhaust gas venting system that can be seen without the use of cameras or other equipment.

Level 2 is appropriate for newly purchased homes or if changes to the system are anticipated, such as switching from an oil-burning furnace to one that uses natural gas. It requires a visual inspection of all internal surfaces, including flue liners and joints. The most common method of meeting this requirement is video scanning with special cameras. In addition to all the actions required in a Level 1 inspection, a Level 2 inspection checks clearances anywhere there is available access for the inspection.

Level 3 is the most detailed and is appropriate whenever hazardous conditions may exist. This level is required if it appears that construction of the chimney area or clearances are inadequate or that safety may have been compromised by some event, such as an earthquake or lightning strike.

NONCOMBUSTIBLE MATERIAL

A material that, in the form in which it is used and under the conditions anticipated, will not ignite, burn, support combustion, or release flammable vapors when subjected to fire or heat. Materials that are reported as passing ASTM E. 136, Standard Test Method for Behavior of Materials in a Vertical Tube Furnace at 750 C, shall be considered noncombustible materials. (220:2-1).

QUALIFIED AGENCY

Any individual, firm, corporation, or company that, either in person or through a representative, is engaged in and is responsible for the connection, venting, installation, inspection, repair, or servicing of heat-producing appliances and who is experienced in such work.

SMOKE

Small gas borne particles of carbon or soot, less than 1 micron in size, resulting from incomplete combustion of carbonaceous materials and of sufficient number to be observable.

SMOKE CHAMBER

The transitional area from the damper opening to the beginning of the flue liner in a fireplace system.

SMOKE TEST

A procedure for ascertaining the tightness of a chimney and for detecting any cracks in a masonry chimney flue or deterioration or breaks in the integrity of a metal chimney flue, and that involves igniting a smoke bomb or building a smoky fire in a fireplace or solid fuel-burning appliance, covering the chimney termination, and checking for smoke escaping through the chimney walls.

SOLID FUEL

Wood, coal, and other similar organic materials and any combination of them.

SOLID FUEL-BURNING APPLIANCE

A chimney-connected device that burns solid fuel designed for purposes of heating, cooking, or both.

SOLID MASONRY CONSTRUCTION

A bonded assembly of stones or solid masonry units.

SOLID MASONRY UNIT

A masonry unit whose net cross-sectional area in every plane parallel to the bearing surface is 75 percent or more of its gross cross-sectional area measured in the same plane.

THIMBLE

A fixed or removable ring, tube, or lining usually located in the hole where the chimney connector or vent connector passes through a wall or enters a chimney or vent.

TYPE B GAS VENT

A vertical or nearly vertical gas vent of venting listed for use with Type B gas vents.

UL LISTED

Equipment materials, or services included in a list published by an organization that is acceptable to the authority having jurisdiction and concerned with evaluation of products or services, that maintains periodic inspection of production of listed equipment or materials or periodic evaluation of services, and whose listing states that either the equipment, material, or service meets appropriate designated standards or has been tested and found suitable for a specified purpose.

VENT CONNECTOR

The pipe that connects a fuel-burning appliance to a gas vent or Type L vent.

WASH

A slight slope or beveled edge on the top surface of a chimney designed to shed water away from the flue liner.